As we know the pump is the hydraulic machine which converts mechanical energy into hydraulic which is in the form of pressure energy this conversion is done with the help of Centrifugal force or centrifugal effect then the Pump which is being used to do this conversion is called centrifugal pump.

A centrifugal pump is a rotodynamic pump that uses a rotating impeller to increase the pressure of a fluid. Centrifugal pumps are commonly used to move liquids through a piping system. The fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or volute chamber (casing), from where it exits into the downstream piping system. Centrifugal pumps are used for large discharge through smaller heads.

Centrifugal pump use a rotating impeller to create vaccum in order to move liquid, impeller is also know as blade

CF have benefit from simple design with few moving parts resulting in lower maintain and costs.

Modern process plants use powerful centrifugal pumps, primarily because of the following factors :

1. The low initial cost.

2. Low maintenance costs.

3. Simple in operation.

4. Ability to operate under a wide variety of conditions.

5. Give a smooth, continuous flow, free from pulsation.

CENTRIFUGAL FORCE

The centrifugal force is a outward force arising from the body;s inertia which body moves in a circular path,the force that acts away from the centers is called CF

The word, ' centrifugal ' is derived from the latin language and is formed from two words

'centri' meaning 'centre' and 'fugal' meaning 'to fly away from'.

Centrifugal - 'to fly away from the centre'.

This is the force developed due to the rotation of a body - solid, liquid or gas. The force of rotation

causes a body, or a fluid, to move away from the centre of rotation.

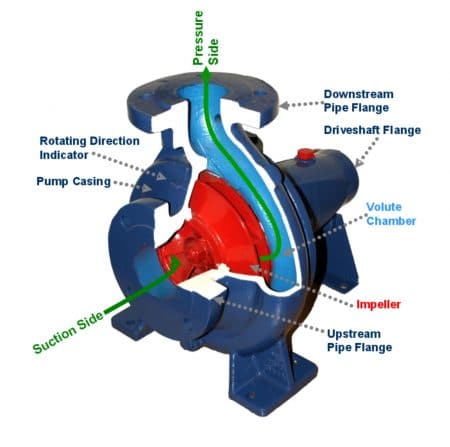

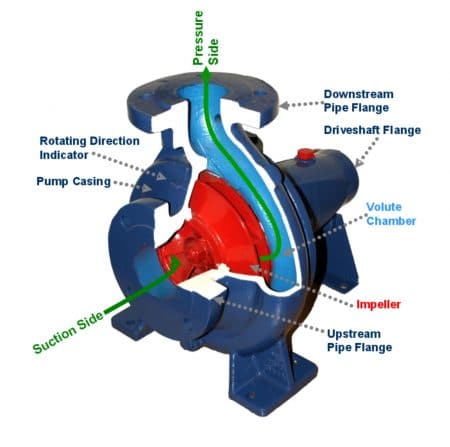

Component pats of Centrifugal pump

There are a few components that virtually every centrifugal pump has in common. These components includes

Centrifugal pump is a hydraulic machine which converts mechanical energy into hydraulic energy by the use of centrifugal force acting on the fluid. These are the most popular and commonly used type of pumps for the transfer of fluids from low level to high level.

Its is used in places like agriculture, municipal (water and wastewater plants), industrial, power generation plants, petroleum, mining, chemical, pharmaceutical and many others.

1. Impeller

It is a wheel or rotor which is provided with a series of backward curved blades or vanes. It is mounded on the shaft which is coupled to an external source of energy which imparts the liquid energy to the impeller there by making it to rotate.

Fig 2: Open, Semi Enclosed and Enclosed Impeller

Impellers are divided into 3 types,

- Open Impeller

- Semi enclosed Impeller

- Enclosed Impeller

2. Casing

It is a pipe which is connected at the upper end to the inlet of the pump to the centre of impeller which is commonly known as eye. The double end reaction pump consists of two suction pipe connected to the eye from both sides. The lower end dips into liquid in to lift. The lower end is fitted in to foot valve and strainer.

Fig 3: Main Components of Centrifugal Pump.

Commonly three types of casing are used in centrifugal pump,

- Volute Casing

- Vortex Casing

- Casing with Guide Blades

3. Delivery Pipe

It is a pipe which is connected at its lower end to the out let of the pump and it delivers the liquid to the required height. Near the outlet of the pump on the delivery pipe, a valve is provided which controls the flow from the pump into delivery pipe.

4. Suction Pipe with Foot Valve and Strainer

suction pipe is connected with the inlet of the impeller and the other end is dipped into the sump of water. At the water end, it consists of foot value and strainer. The foot valve is a one way valve that opens in the upward direction. The strainer is used to filter the unwanted particle present in the water to prevent the centrifugal pump from blockage.

No comments:

Post a Comment